The challenge faced by agrosystems

Alongside global population growth and climate change, the increasing densification of urban space is one of the key challenges faced by agrosystems. The space and infrastructure boundaries between urban centres and peri-urban areas are increasingly becoming blurred by the mega-trend of urbanisation. Given the simultaneous scarcity of available agricultural land, today’s agrosystems will no longer be able to feed the growing population increasingly living in metropolitan regions. New approaches to food production are therefore required.

The vision

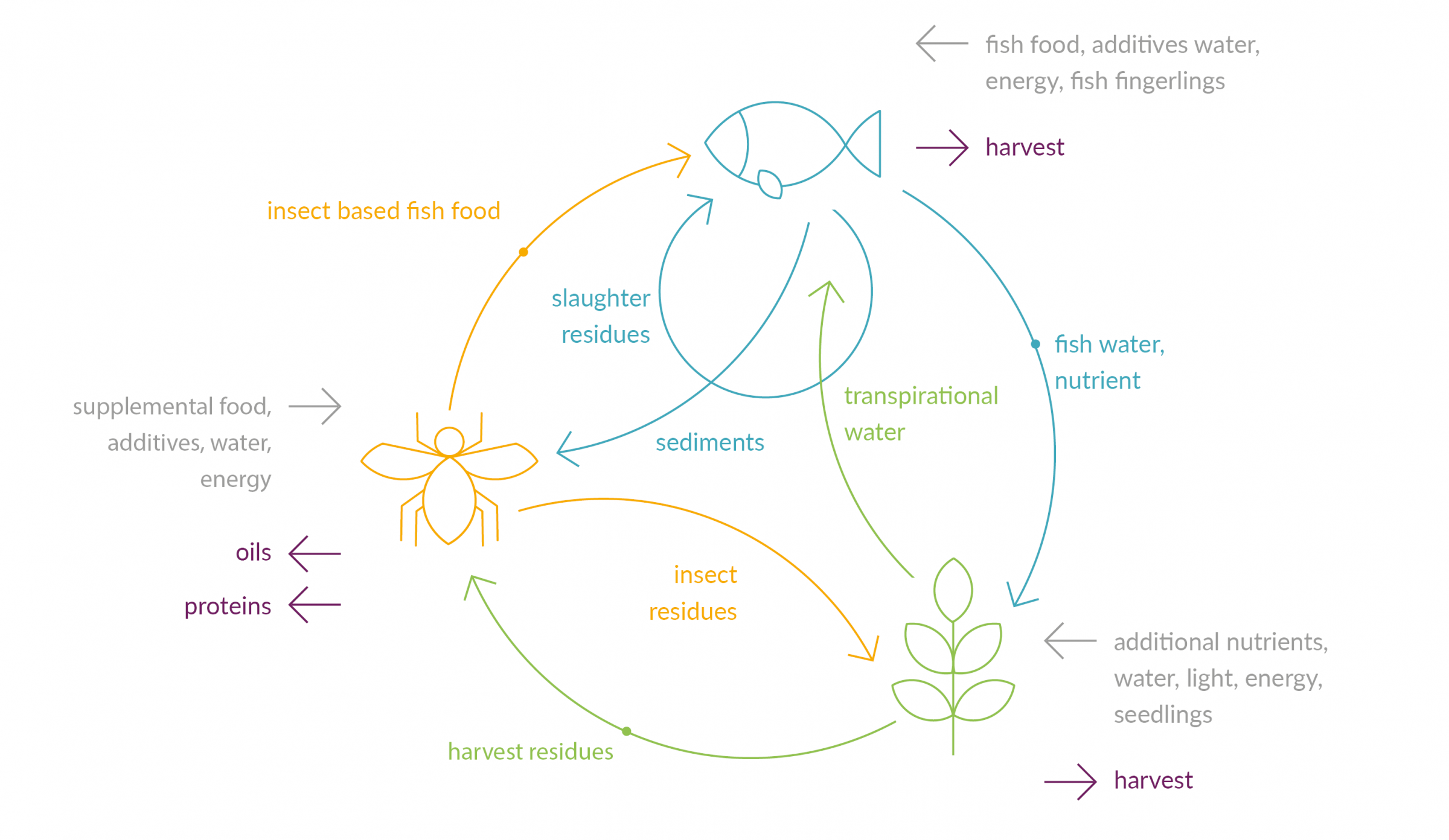

The CUBES Circle (Closed Urban modular Energy and Resource-efficient Agricultural Systems) project pursues a vision of the intelligent networking of various agricultural production systems in closed energy and substance cycles. Production units of plants, insects and fish that communicate with each other are to be cultivated in the CUBES, utilising the waste materials of the respective other production processes. Here the basic principles of passing on substances correspond to those of natural systems across several levels from producers to secondary consumers.

Thanks to the ISO-standardised and stackable basic shape as well as the mobile nature of the CUBES, they are extremely versatile in application – from urban to suburban space to desert-like sites. Integrating the principles of various closed cultivation processes into a new process chain is the goal. It is of crucial importance for the project that the individual links of the chain have open interfaces for intelligent inter-networking and control. This permits the realisation of synergies, successful integration into the urban environment and the implementation of resource-optimised production with almost no waste. The CUBES Circle is also resilient in regard to changing ecological and socio-economic conditions.

More information about the project and the consortium is available here.

Coordinator

Prof. Dr. Dr. Christian Ulrichs

Humboldt University of Berlin

Faculty of Life Sciences

Albrecht Daniel Thaer-Institute of Agricultural and Horticultural Sciences

Division Urban Plant Ecophysiology

Lentzeallee 55-57

14195 Berlin

Tel.: +49 30 2093 46420

Fax: +49 30 2093 46440

E-Mail: mail@cubescircle.de

Follow us on:

Instagram

ResearchGate

LinkedIn

Project partners

Humboldt University of Berlin

Prof. Dr. Dr. Christian Ulrichs

Prof. Dr. Uwe Schmidt

Prof. Dr. Christoph-Martin Geilfus

Prof. Dr. Bernhard Grimm

Prof. Dr. Linda Onnasch

Prof. Dr. Peter Feindt

Chemnitz University of Technology

Prof. Dr.-Ing. habil Stefan Streif

Technische Universität Braunschweig

Prof. Dr.-Ing. Christoph Hermann

Weihenstephan-Triesdorf University of Applied Science

Prof. Dr. Heike Mempel

The Julius Kühn Institute

Prof. Dr. Stefan Kühne

The Leibniz-Institue of Freshwater Ecology and Inland Fisheries

Prof. Dr. Werner Kloas

Biological consulting

Dr. Matthias Schöller

gsub - Society of Social Business Consultancy

Dr. Dieter Simon

Conviron

Dr. Carsten Richter

Rewe Group

Step Systems GmbH

Scientific advisory board

Prof. Dr. Wolfgang Bokelmann

Dr. Ludger Breloh

Jacqueline Lawina Were

Dr. Marco Wopereis